Suppliers are important partners to WIN's sustainable development. To strengthen our partnership with suppliers, improve their quality, WIN established the "WIN Supplier Code of Conduct" to request suppliers to strictly abide by the contents of the Code of Conduct in all commercial operations and full compliance with the laws and regulations of the country/region of operations.

97%

Completion ratio of the sustainability

management self-assessment by suppliers

of direct materials

100%

Ratio of new suppliers in the supply

chain that signed the "WIN Supplier

Code of Conduct".

Supply Chain Management

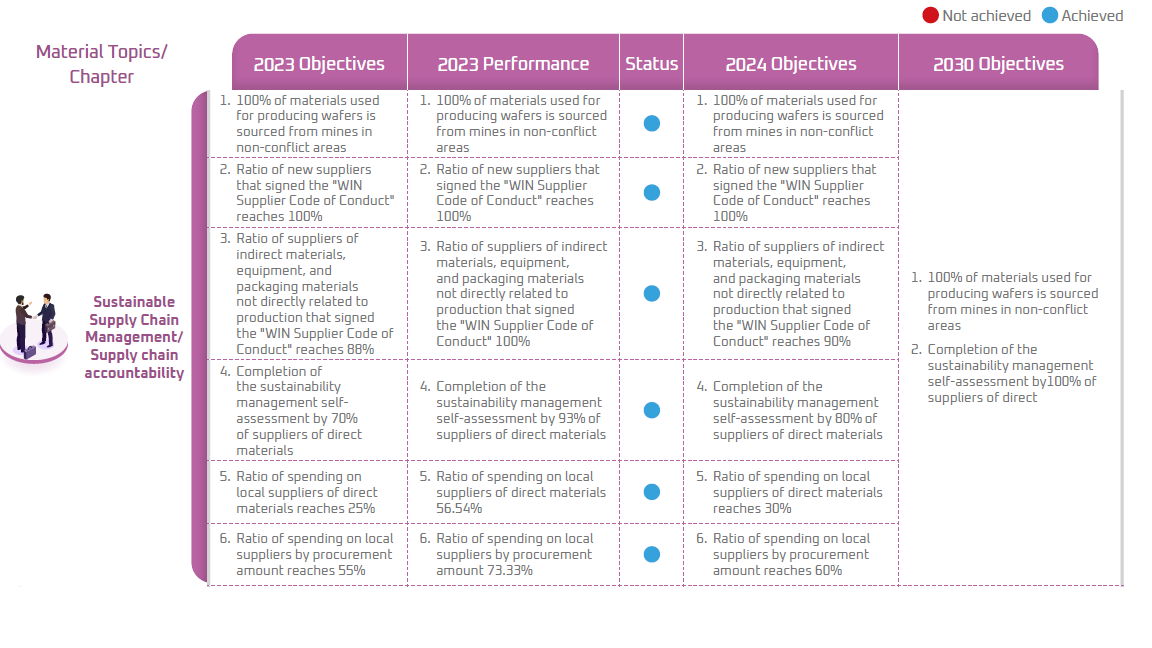

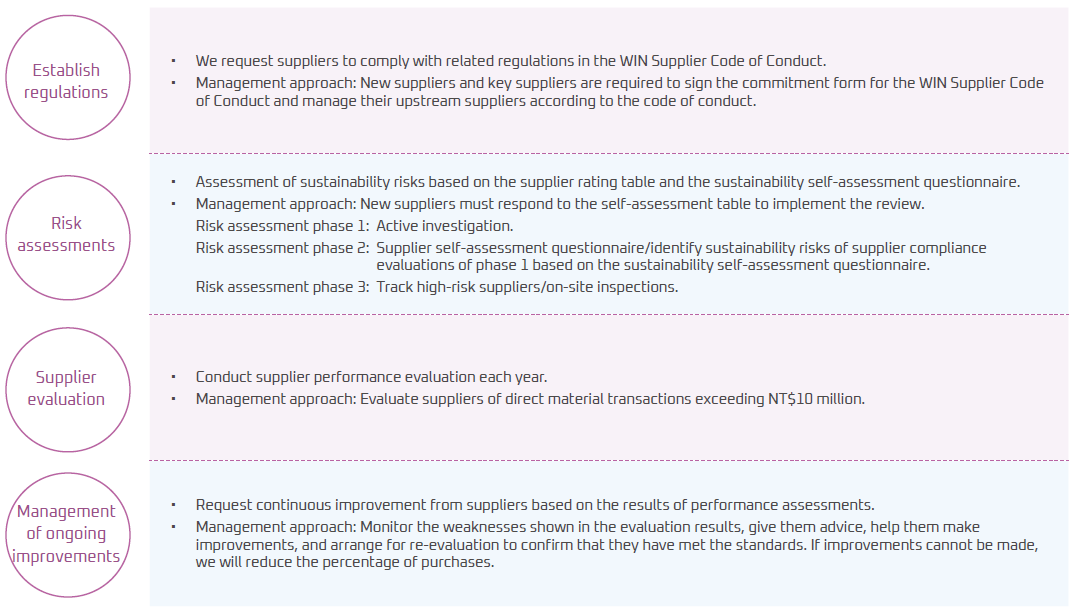

WIN is committed to its responsibility for environmental and social aspects. WIN expects its supply chain to develop sustainably and move towards a friendly environment and a safe workplace, and to follow ethical standards. WIN conducts due diligence on upstream supplier-related risks and promotes the sustainable development of upstream and downstream suppliers through the four aspects of the supplier management process: formulate standards, risk assessment, supplier evaluation, and continuous improvement.

Supply Chain Management Strategy

Raw Material Prioritization Assessment

WIN identifies critical raw materials based on their proportion of total procurement value and usage volume, prioritizing those with higher cost contributions for further analysis. In 2024, for example, wafers, precious metals, chemicals, and gases accounted for nearly half of the company’s total procurement value.

Raw Material Traceability

WIN adopts a risk-based raw material traceability mechanism. When international political, economic, geopolitical, or other environmental and social risks pose potential impacts on the supply of specific raw materials, the company initiates supplier audits and risk assessment procedures. For instance, in response to U.S.–China trade tensions, WIN traced the origin and confirmed the supply stability of key metal materials to ensure that they were not subject to sanctions or export restrictions, thereby maintaining uninterrupted production.

Reducing Negative Environmental and Social Impacts of Raw Material Production

● WIN integrates recycled content into its supply chain as a key measure to lessen the environmental footprint of upstream mining and refining, including reducing carbon emissions, conserving water, and minimizing heavy metal contamination.

● Supplier Code of Conduct & Conflict Minerals: WIN requires all suppliers to sign the Supplier Code of Conduct, committing to prohibitions on child labor, forced labor, discrimination, and unsafe working conditions, and encouraging adoption of RBA standards. Suppliers of metal materials must also provide a “No Conflict Minerals” declaration and submit Conflict Minerals Reporting Template (CMRT) data to ensure supply chain responsibility and transparency.

● Third-party verification of sustainability report: WIN’s 2024 Sustainability Report was prepared in accordance with GRI Standards and assured by AFNOR Asia Ltd., receiving a moderate assurance opinion under AA1000 V3 to enhance report credibility.

● Supplier self-assessments and performance management: WIN conducts environmental and social responsibility audits and questionnaire surveys for high-risk suppliers to ensure production sources do not cause negative environmental or social impacts. In 2024, the company achieved a supplier self-assessment response rate of 97% and exceeded its local procurement target, reflecting a well-established supplier sustainability management system.

Targets for the Use of Recycled Materials

WIN sets annual targets for the proportion of recycled content for multiple materials. Targets for 2025 include:

● Gold: 95% (2024: 88%)

● Palladium: 90% (2024: 85%)

● Platinum: 90% (2024: 85%)

● Silver: 90% (2024: 88%)

● KI:I2: 80% (2024: 70%)

Internal Stakeholder Training

WIN regularly organizes training programs on raw material compliance and sustainable procurement for staff in supply chain, quality assurance, procurement, and engineering departments to strengthen company-wide awareness and accountability regarding sustainable raw materials.

Regulation

WIN firmly believes that a sustainable supply chain is the key to the Company's success in long-term operations. To ensure suppliers understand and establish sustainable operations, we referenced information published by the Responsible Business Alliance (RBA) and related international regulations to establish the WIN Supplier Code of Conduct, requiring suppliers to comply with the code in their business conduct in labor, health and safety, environment, corporate ethics, and management systems and fully comply with the laws and regulations of the countries/regions of their operations. In addition, we have implemented a traceability system for our raw materials to ensure responsible sourcing and minimize environmental and social impacts throughout our supply chain. We also require suppliers to communicate these requirements to their suppliers and supervise the implementation status of the next level of suppliers.

Suppliers that have completed the survey and signed the "WIN Supplier Code of Conduct" in 2024

| Location | United States | Europe | Taiwan | Asia Pacific | Others | Total | |

|---|---|---|---|---|---|---|---|

| Direct raw material supplier | Number of companies surveyed | 4 | 4 | 79 | 16 | 0 | 103 |

| Response rate | 100% | 100% | 100% | 100% | - | 100% | |

| Indirect materials, equipment, and packaging materials not directly related to production | Number of companies surveyed | 15 | 11 | 764 | 13 | 1 | 804 |

| Response rate | 100% | 100% | 100% | 100% | 100% | 100% | |

| Critical suppliers | Number of companies surveyed | 5 | 5 | 81 | 14 | 1 | 106 |

| Response rate | 100% | 100% | 100% | 100% | 100% | 100% | |

| New supplier | Number of companies surveyed | 1 | 1 | 38 | 0 | 0 | 40 |

| Response rate | 100% | 100% | 100% | - | - | 100% | |

WIN Supplier Code of Conduct

Sustainable Raw Material Policy

ANTI-CORRUPTION AND ANTI-BRIBERY POLICY OF WIN SEMICONDUCTORS CORP

Environmental Protection, Safety and Health Requirements for Supplier / Vendor /

Subcontractor / Contractor

Subcontractor / Contractor

Information Security Notice to Supplier

Prevention of Counterfeit Products

Statement of Safety and Health Management

Requirement for suppliers of raw material and packaging material by WIN:

Notice for management changed

Any change on products including component, concentration of harmful material or location of manufacturing, suppliers must take the initiative to inform WIN.

Declaration for not use of haz ardous substances

Suppliers must confirm all of the raw material (recycled raw material included) and packing material do not contain the hazardous substances which list on Annex I. During the time of suppliers' annual evaluation and applying for new supplier and material assessment, suppliers must sign in Annex I.

Testing Report

- During the time of suppliers' annual evaluation and applying for new supplier and material assessment, suppliers must provide the testing report of raw material.

- Testing report must be done in a fair laboratory by the third party. The process must meet the regulation of HSF.

- Testing report provided by suppliers of raw material is valid for one year.

- Supplier must provide testing report according to the following classification:

| Types of suppliers | RoHS | REACH |

|---|---|---|

| Wafer | V | V |

| Metal | V | - |

| Polyimide | V | V |

Declaration of Metal Conflict-Free

The supplier of metal shall use the latest "Conflict Minerals Reporting Template"(CMRT) by RMI to

disclose the mental sources and the smelters and refineries in the supply chain.

In 2024, WIN used approximately 15 metric tonnes of iron/steel (30% recycled content), 1.063 metric tonnes of copper, 0.09 metric tonnes of nickel, 0.034 metric tonnes of titanium, and 0.011 metric tonnes of aluminium. Copper, nickel, titanium, and aluminium contained no recycled material. No cobalt or lithium was used during the reporting year.

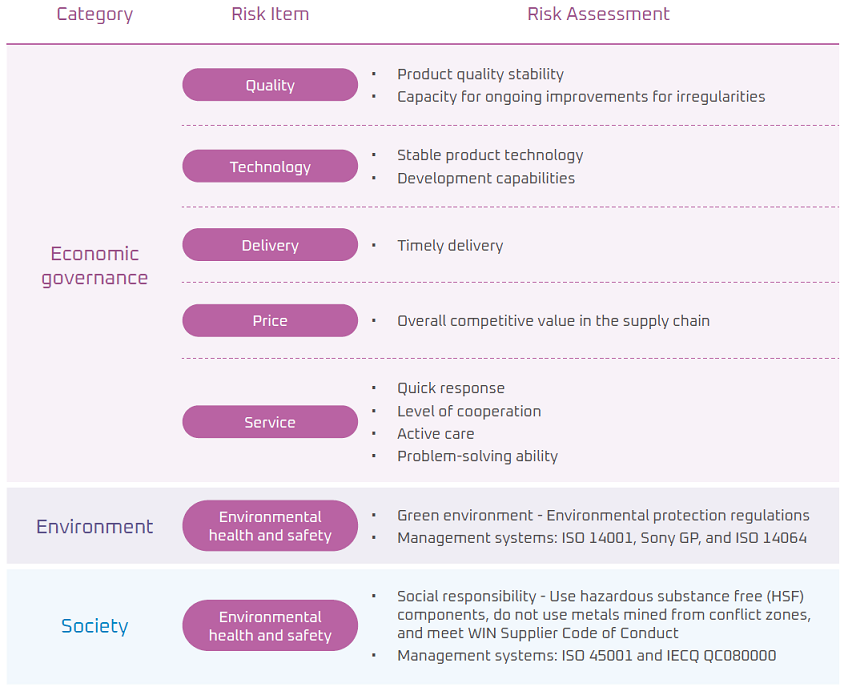

Supply Chain Management Risk Assessment

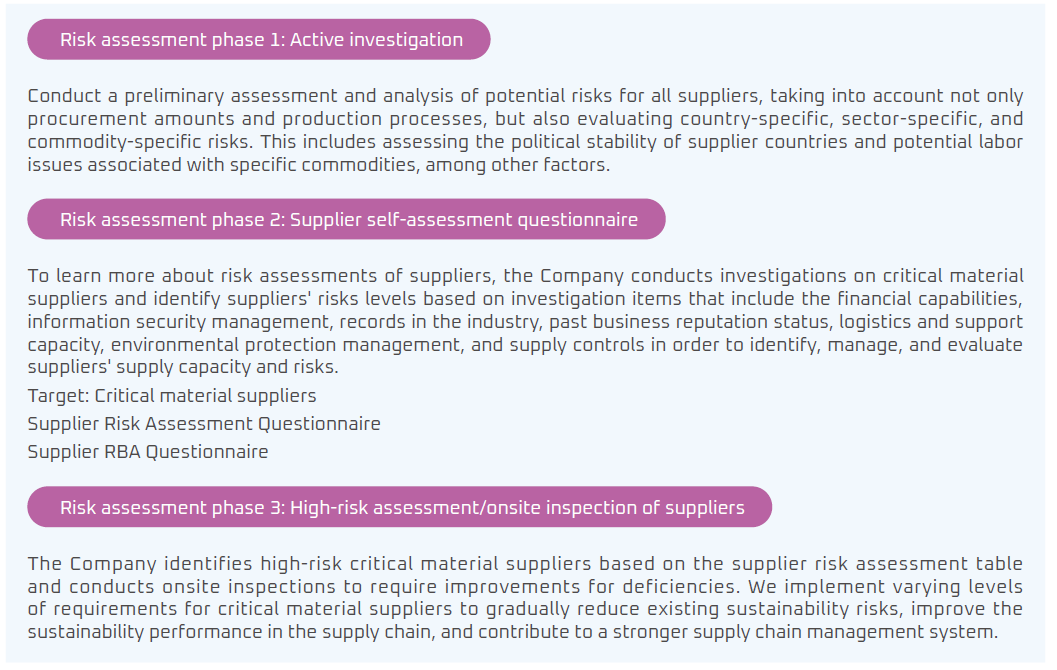

WIN manages sustainability risks of the supply chain to learn about the sustainable development status of the supply chain. WIN's management approach is as follows:

1. Risk Identification: We categorize, analyze, and further identify potential risks faced by the Company or supply chain.

2. Risk assessment: Use analysis methods to determine the probability and losses of specific risks.

3. Risk control: WIN selects suitable management tools based on the management goals to reduce risk.

We survey and assess the sustainability risks of suppliers through a three-stage process every year.

Supplier Evaluation

WIN regularly assesses suppliers' compliance with the risk management items and choose partnerships based on supplier compliance and continuous performance. WIN requires suppliers to make improvements to their weaknesses during annual supplier evaluations, and also communicates company policy. We periodically examine the status of the supply chain, and implement systematic management to update supply chain status at any time, formulate response strategies, and lower the impact of risks.

Existing Supplier Evaluation

With regard to raw materials supply chain evaluation and management, WIN rates its suppliers according to their performance in the previous year regarding quality, technology, delivery dates (including premium freight), price, service (including customer notifications of special circumstances and customer interruption), and environmental safety and health practices. Materials suppliers are graded according to their evaluation scores, and those with low scores are requested to propose improvement strategies. WIN organizes onsite audit plans based on annual evaluation results. We also audit main suppliers at least once every three years. For suppliers who are still unable to meet the requirements of stability after counseling, the supplier replacement mechanism will be activated after communication. We used different audit methods due to the pandemic, including documentary audit, remote audit, and RBA questionnaire.

In 2024, 106 tier-1 significant suppliers accounted for 87% of the company’s procurement value, while there were 110 non-tier-1 significant suppliers.

In 2024, A-level raw material suppliers represented 32% of the total, B-level suppliers 58%, and C-level suppliers 9% (five suppliers in total). All five C-level suppliers were assisted during the year in addressing deficiencies, and all identified issues were corrected, achieving a 100% completion rate.

Evaluation of new suppliers

WIN's review and approval or all new raw materials are carried out as follows: first they are tested by the engineering department, and if found to have complied with the standards, the vendor of the materials is evaluated by other relevant auditing departments, such as EHS, legal affairs, procurement, quality assurance, and material management for supply risk and to ensure subsequent security in the supply of materials. Once the vendor has passed all evaluations, it will become WIN's qualified supplier and will then undergo WIN's annual performance assessment. The Company's audit team will subsequently arrange on-site audits based on the annual assessment results.

The Company established Procurement Management Procedures, Supplier/Contractor Evaluation Management Procedures, etc., evaluates the effect of transactions with a supplier on quality on the environment, and verifies the actual situation.

Supplier sustainability evaluation

To lower potential risks in the supply chain, raw materials suppliers with transaction amount reaching NT$3 million and above are required to complete the supplier sustainability self-evaluation questionnaire. In 2024, the questionnaire was sent to 60 suppliers, with around 97% completing the questionnaire. The procurement unit assesses and confirms the ESG compliance of suppliers. Oversight is conducted by the highest-ranking manager of the procurement unit and Chairperson of the ESG Committee, President Steve Chen of the Administration Division. Upon identifying deficiencies, improvement suggestions are provided, and these factors are considered in procurement decisions. Suppliers with better ESG performance are prioritized. Furthermore, suppliers are expected to meet minimum ESG requirements within two years; failure to do so will result in exclusion from contracting. We also offer capacity-building programs aimed at systematically improving supplier practices on specific ESG topics, which include auditing their own suppliers to enhance compliance throughout the supply chain. Moving forward, we will continue sustainability assessments to monitor the supply chain and ensure that suppliers adhere to the Supplier Code of Conduct and meet the ESG standards.

In addition, we will regularly review and enhance our purchasing practices to ensure alignment with the Supplier Code of Conduct and prevent potential conflicts with ESG requirements.

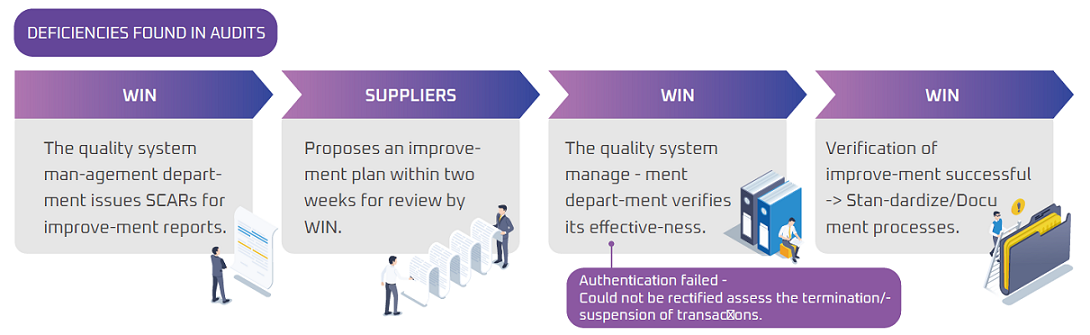

Management of Ongoing Improvements in the Supply Chain

In order to prevent the risks of supply disruptions or discontinuations, which are often unavoidable, WIN performs ongoing risk assessments and audits of major raw material suppliers. The Company also established contingency plans with respect to the geographic locations of suppliers' production facilities. In the event of a major supply disruption incident, WIN will be able to respond promptly to minimize the impact. The Company also updates and reviews suppliers' inventory levels and production scheduling plans on a monthly basis and integrates the information management approaches of the supply chain's upstream and downstream players in order to minimize the anticipated risks.

WIN assists and guides suppliers and contractors into improving the work environment to improve safety and health concepts and sustainability management awareness. We organize labor safety education and training session for suppliers and contractors once every month. Contents include: WIN's sustainability management mechanisms and goals, safety and health regulation promotion, and increasing the awareness of legal liabilities for occupational hazards. We use seminars to communicate future management requirements and key items.

Education and Training of Procurement Personnel on Sustainable Supply Chain Management

Purpose: To train procurement in responding to sustainable supply chain management policies.

Have sufficient management concept and correct use of management methods to promote the stable

supply chain and achieve sustainable development goals.

Action/Strategy:

1. Regularly hold sustainable supplier management education and training internally.

2. Procurement promotion and implementation of RBA policies and management.

3. Set ESG KPIs and management goals, and conduct regular management tracking.

4. DJSI (Dow Jones Sustainability Index) corresponds to ESG policy management.

5. Conflict mineral metal management.

6. Continuous risk management of the supply chain.

7. Sustainable supplier audit.

8. Periodically hold educational and training sessions on sustainable raw material management.

For more information, please read full article

Download