Customer satisfaction is one of WIN's core values. As a foundry service provider, WIN remains committed to protecting customer privacy and confidential information.

0

cases

There has been no case of leaks of

customer privacy in WIN.

Scored

94.7

Customer satisfaction were above

target score 75.

Protect Customer Privacy

OEM service providers must qualify through rigorous and laborious customer verification procedures to obtain purchase orders from customers. As technology advances, companies' important confidential information may be stolen by malicious individuals, and leaks of confidential information may cause the loss of purchase orders and business reputation, and affect the Company's operations and development. WIN has always placed great emphasis on protecting customer privacy and we have therefore won the continuous trust of customers and provide services to more customers. Formulate a "Confidential Information Management Policy" and an "Information Security Policy" to detail the definition of confidential information and related operating specifications to provide the highest level of protection for customer confidential information including customer contracts, orders, technology and other data. We pay close attention to customer demands for information security and restrict access to customer data and files through permissions. We have passed all information security audits implemented by customers each year. We have maintained relationships of trust with customers but we seek to do more. We shall continue to strengthen information security and exceed customer expectations.

- Obtain ISO/IEC 27001:2022 Information Security Certification.

- Personnel management: The Company continues to strengthen employees' awareness of information security. In addition to announcing them on WIN's internal website for employees, we also specify requirements in employees' commitment statements.

- System security: To protect the confidentiality and integrity of customer information, we continue to strengthen system and data security including the establishment of a comprehensive anti-virus system and file encryption systems and mechanisms. We also implement rigorous access control and management for customer data and files.

- Audit prevention: WIN continues to implement weakness scans on the website and servers each year based on the Company's internal audit procedures to strengthen data security for customers and prevent theft by malicious external entities. We also rectify weaknesses based on the assessment report to complete consistent protection from inside to outside.

We continue to monitor our use of customer personal data and throughout year 2024, we did not use collected personal data for any secondary purposes other than the specific purposes for which the personal data was first collected. Please see the chapter about Information Security Management for information security management measures. There has been no case of leaks of customer privacy in WIN. The Company shall continue to strengthen information protection software and hardware facilities, protect customer privacy, and ensure zero leakage of customer information.

Customer Satisfaction

-

WIN is committed to the development and innovation of manufacturing technologies, pursuing quality with a spirit of continuous improvement to deliver high-quality products that deliver customer satisfaction. If any product or service poses a risk to the safety or health of consumers or other stakeholders, we will recall the batch in question or suspend the service, investigate the facts, and propose corrective and improvement plans. To manage customer complaints and the complaint process, we have established the "Customer Complaint and Abnormal Product Handling Procedures" and the "Customer Complaint/Return Management Procedures". The Customer Engineering Department is responsible for handling complaints or claims, providing a response within 24 hours, and completing a preliminary analysis within 7 working days. From 2021 to 2024, there were no product recalls due to hazards to human health and safety. To continuously deliver customer satisfaction and refine quality management, we obtained ISO 9001 certification. In addition, we have established and promoted the quality management system in accordance with international quality standards. In 2024, a total of 715 people participated in professional quality training, totaling 759.28 training hours.

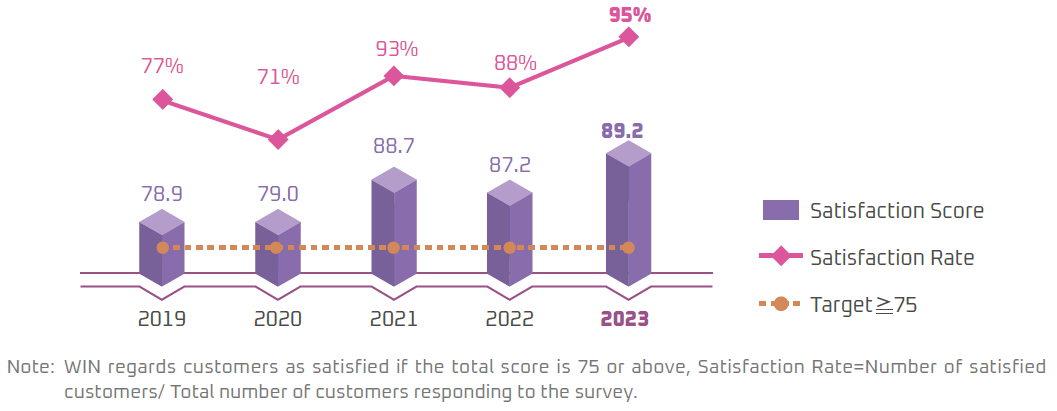

Customer satisfaction survey statistics

A satisfaction survey was conducted in 2024, targeting the top 20 major clients of the previous year. The Microwave Transmission Sales Center distributed the questionnaires, which were then collected and analyzed by the Quality Assurance Department. Customers were asked to rate their satisfaction with WIN's service, technology, quality, delivery time, and circuit design support, with scores of 1 to 5 representing unacceptable to very satisfy. For items with a score below “3”, the Quality Assurance Department will take responsibility to confirm cases of customer dissatisfaction and their causes so that improvement or proper measures can be taken to rectify any problems going forward. In 2024, we achieved significant increases in each rating category, but WIN will continue to make every effort to provide customers with the best technical services.

Product Accountability

-

Purpose

-

To meet international green procurement trends and customer demand, WIN fulfills product responsibilities, establishes comprehensive management systems, and discloses information on the official website for reference by customers. We provide customers and consumers with products that conform to international green environmental protection regulations.

-

-

Product Safety and Hazardous Substance Management

-

To comply with the expectations of customers and stakeholders, WIN has established hazardous substance-free management procedures, actively checked the ingredients of raw materials, and required all raw materials have to meet EU implemented the Restriction of Hazardous Substances Directive (RoHS) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). WIN also require our products to meet the EU's regulations and other related hazardous substance-free regulations.

To protect the environment and people's safety and health, WIN prohibits or restricts the purpose of use and quantity of hazardous substances in its products and raw materials, based on international directives and customer requirements. Additionally, it has formulated a hazardous substance checklist for compliance by its suppliers and employees. WIN's checklist is composed of two major categories:

● List of Substances Prohibited or Restricted in Products

● List of substances in a product for which customers have been informed

-

WIN specifies in purchase contracts and order forms that new material suppliers must comply with WIN's supplier management procedures, and that the provided materials may not contain hazardous substances as defined by WIN. Furthermore, suppliers must regularly provide product testing reports and undertake annual supplier assessments as requested by WIN. Regarding new materials, the Technology R&D Department must abide by WIN's hazardous substance free management procedures when determining product specifications and selecting materials to ensure that new materials are hazardous substance free.

-

WIN requests all of its suppliers to provide declaration of not using of hazardous substances or third-party testing reports as part of the basis of evaluations which helps to ensure that the raw materials which WIN uses are free of hazardous substances.

-

To satisfy customers and other stakeholders' demands for HSF products, WIN products are subject to third-party testing at least once every year to ensure that all of its products are in line with international green environmental standards. Inspection items include product HSF inspections based on REACH, RoHS, PFOS & PFOA, and halogen-free regulations to ensure that all product meet international green environmental protection regulations. Since the commencement of product inspections, all WIN products have been verified as 100% conforming to related HSF regulations. WIN products have not caused any harm to people's physical health or environmental contamination in 2024.

-

-

Information Disclosure Regarding Hazardous Substance Free by WIN

-

A Hazardous Substance Free (HSF) section was set up in the E-Service section on WIN's official website, providing the following information pertaining to hazardous substance free and conflicting minerals for customer access:

● Declaration for Hazardous Substance Free

● Declaration of Metal Conflict-Free

● Conflict Minerals Reporting Template

● Third-Party Product Testing Report for the Year

-

-

In response to the EU WEEE Directive

Although the semiconductor components produced by WIN are not end products and are not directly applicable to the scope of the WEEE Directive, WIN will also cooperate in providing relevant information if the end product customer has WEEE compliance requirements to help customers comply with regulations.

-

Chemical Risk Assessment

WIN Semiconductors values a safe and healthy working environment. To effectively control the use of hazardous chemicals, the company assesses the risk level of each chemical based on its health hazards, potential for dispersion, and usage volume, and applies corresponding graded management measures. Formal procedures, including the “Chemical Substance Management Procedure” and the “Hazardous Chemical Assessment and Graded Management Procedure,” are established in line with the concept of Chemical Control Banding (CCB). The assessment incorporates GHS health and environmental hazard classifications, the degree of chemical dispersion in air, and usage volume, to determine the chemical’s risk level. Based on hazard group and exposure level, a risk matrix is used to apply graded management and select appropriate management and exposure control measures, thereby preventing potential harm from chemicals, reducing occupational incidents, and minimizing environmental pollution risks.

-

● Health hazards: Evaluate potential impacts on human health, including skin corrosion/irritation, acute toxicity, carcinogenicity, and other relevant toxicological effects.

● Dispersion potential: Assess the likelihood of the substance dispersing into the air by considering its physical form, volatility, or dustiness.

● Usage volume and frequency: Evaluate the amount used and the frequency of handling to determine potential exposure levels.

● Exposure routes: Identify possible exposure pathways, including inhalation, skin contact.

-

● Risk matrix application: Combine hazard characteristics and exposure assessment results to determine the overall risk level and select appropriate management and control measures.

● Control measures: Implement ventilation systems, local exhaust devices, personal protective equipment, and other controls to reduce exposure.

● Monitoring and maintenance: Conduct regular workplace and environmental monitoring to confirm chemical concentrations remain within safe limits and verify the effectiveness of control measures.

To safeguard employee health and environmental safety, WIN conducts hazardous chemical assessment and graded management on a regular basis. If there is any change in chemical type, operating procedure, or process condition that may increase exposure risk, reassessment and reclassification are carried out promptly to ensure that risks under real-world conditions are effectively controlled.

-

-

Hazardous Substances Substitution and Phase-out Program

WIN is committed to reducing and managing hazardous substances in our products, processes, and raw materials to safeguard human health and protect the environment. We strictly comply with regulatory requirements such as RoHS, REACH, and the PFOS & PFOA, and strive to go beyond compliance by exceeding customer expectations. We are dedicated to continuously strengthening our chemical management practices, including routine substance inventory, enhanced supplier controls, and proactive substitution of high-risk materials. Through active collaboration with industry associations and sustained investment in R&D, we aim to accelerate the transition toward safer, more sustainable alternatives.

Since 2021, WIN has allocated dedicated budget and personnel to launch a program to substitute and ultimately phase out N-Methyl-2-Pyrrolidone (NMP). Through active engagement with industry associations, we have identified feasible alternatives and are conducting ongoing evaluations and trials. Starting in 2025, WIN sets an NMP reduction target, with the expectation of fully phasing out and achieving 100% substitution by 2035, thereby eliminating potential risks to human health and the environment.

WIN will continue to monitor changes in international regulations and customer requirements to ensure full compliance. Progress toward our hazardous substances substitution and phase-out targets will be transparently reported in our annual sustainability disclosures.

Sustainable Products

-

We continuously develop new technologies to assist our customers in producing energy-efficient products.

We are committed to the development of new technologies and we continue to introduce high-performance technology platforms to produce more energy-efficient and energy-saving products for the semiconductor communication industry. We develop products based on the evolution of our customers' related products in different communication sectors, such as mobile phones, wireless networks, radars, and satellites. We contribute to global energy conservation and electricity consumption reduction with the continuous support of customers and adoption by consumers.

-

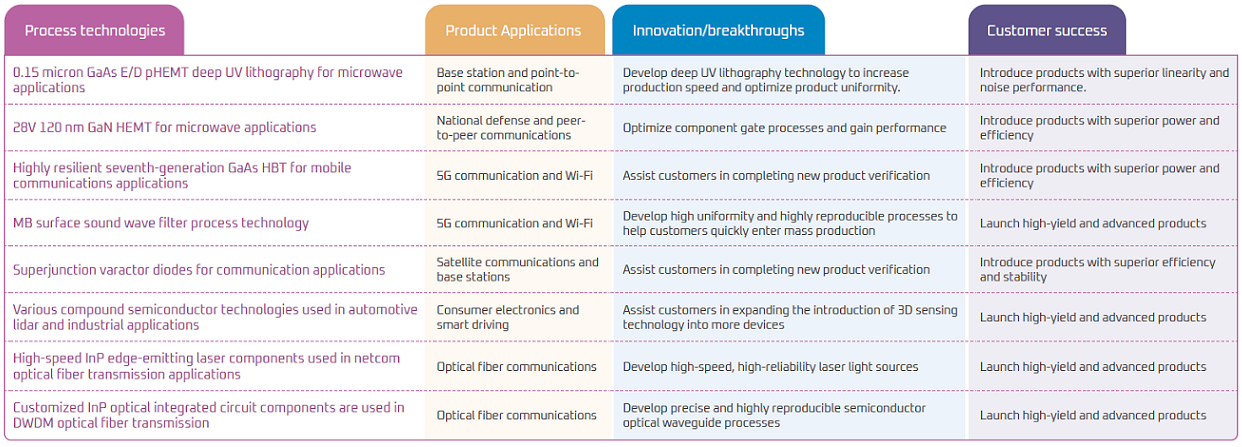

More Advanced and Efficient Technology Platform

WIN holds a leading position in the compound semiconductor sector and continues to launch advanced process technologies. We use a diverse range of technology platforms that cover communication product applications in a wide range of frequencies. We also use outstanding process integration to help customers develop communication and consumer electronic products. In response to the global impact of global warming, WIN plays an important role in energy conservation and carbon reduction for the world in various types of high-performance technology platforms. We also improve multi-functional chip integration and increase the chip density to enhance customers' competitive advantages and launch strong and highperformance products.

In terms of consumer electronics, the technology platforms of each generation have improved and the next-generation technologies are becoming more energy-efficient compared to the first generation. 5G communication applications, as it enters higher frequency fields, can transmit a larger amount of data. The efficient evolution of technology platforms is our ongoing goal.

In addition to the aforementioned consumer products, we also have related technology platforms for applications such as radar, low Earth orbit satellites, and point-to-point transmission, which promote and enhance long-distance transmission and communication coverage. As they are updated, their performance has increased and we also enhance the competitive advantages of customers' products. -

Social Contribution Responsibility

Smart-phones, public infrastructure, and related communication hardware facilities make life more convenient for the public. They also accelerate the exchange of information and knowledge between people which becomes even more critical during emergencies. WIN helps customers produce new products in all communication sectors which facilitates improvements in communication and benefits future societies. By integrating WIN's multi-functional chips, reducing the critical dimension of technology platforms, and improving process capabilities, we greatly reduce wafer manufacturing quantity and the dimensions of electronic products to protect the Earth's environment to promote energy conservation, carbon reduction, and common prosperity for both customers and WIN.

For more information, please read full article

Download